Metal Roof Coating Experts

Professionals prepare the surface thoroughly before applying a durable coating to ensure maximum adhesion and protection.

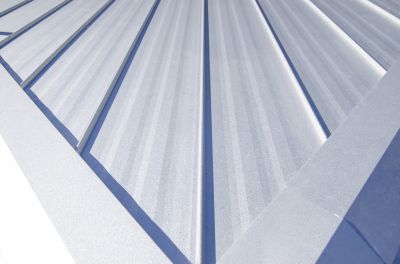

A well-coated metal roof exhibits a sleek appearance and enhanced resistance to environmental elements.

Inspection ensures the coating is applied evenly and adheres properly, extending the roof's lifespan.

The application of a metal roof coating typically takes between one to three days, depending on the size of the roof and the complexity of the surface. A professional team assesses the existing roof condition, cleans and prepares the surface, and applies multiple layers of coating for optimal protection. This process involves surface cleaning, rust removal, and sometimes minor repairs to ensure the coating adheres properly and provides maximum benefit.

Hiring a professional for metal roof coating ensures the job is completed efficiently and correctly. Experienced technicians understand the nuances of different coating products and application techniques, which helps prevent issues such as peeling, bubbling, or uneven coverage. Proper installation by experts can lead to a longer-lasting, more effective protective layer that maintains the roof’s integrity and appearance over time.

Metal roof coatings provide a tough barrier against weather, corrosion, and physical damage, extending the roof’s lifespan.

Reflective coatings can reduce heat absorption, leading to lower cooling costs and improved indoor comfort.

Applying a coating can delay costly repairs and reduce the frequency of roof replacements.

Completed coating work showcasing a uniform, protective layer.

Surface cleaning and rust removal prior to coating application.

Final check to ensure even coverage and adhesion.

Proper maintenance and timely re-coating can preserve the appearance and functionality of a metal roof for decades. Regular inspections help identify areas that may need touch-ups or repairs, ensuring the protective layer remains intact. When considering a coating project, consulting with experienced professionals guarantees the application meets industry standards and provides the desired longevity.

Contacting qualified specialists for a metal roof coating service provides confidence in the quality of work and the longevity of the coating. Professionals bring expertise in surface preparation, product selection, and application techniques, ensuring a durable, weather-resistant finish that enhances the roof’s performance and appearance.

Showcasing the final result of a professionally coated metal roof.

Application of protective layers on a metal roof by trained technicians.

A reflective coating enhances energy efficiency and aesthetics.

To receive a quote for metal roof coating services, filling out the contact form is recommended. Detailed information about the roof size, condition, and desired outcomes helps ensure an accurate and timely response. Professional consultation can provide clarity on the best coating options and maintenance plans to maximize the roof’s lifespan.