Metal Roof Coating Benefits and Timing

Optimal conditions for metal roof coating include dry weather with low humidity, ensuring proper adhesion and curing.

Temperatures between 50°F and 85°F are ideal for applying coatings, preventing issues related to rapid drying or improper bonding.

Spring and fall typically offer stable weather patterns, reducing the risk of rain or extreme temperatures during application.

Ways to make Metal Roof Coating Service work in tight or awkward layouts.

Popular materials for Metal Roof Coating Service and why they hold up over time.

Simple add-ons that improve Metal Roof Coating Service without blowing the budget.

High-end options that actually feel worth it for Metal Roof Coating Service.

Finishes and colors that play nicely with Metal Roof Coating Service.

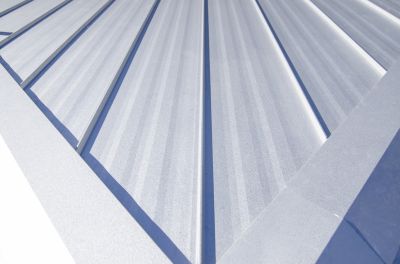

Metal roof coating services are essential for extending the lifespan of metal roofing systems. Coatings provide a protective barrier against corrosion, UV damage, and weather-related wear. Proper application timing ensures maximum effectiveness, with ideal conditions promoting adhesion and durability. Coatings can improve energy efficiency by reflecting solar heat, which can reduce cooling costs in warmer months. Regular maintenance and timely coating applications can significantly enhance the longevity of metal roofs, often doubling their service life.

Protects against corrosion, enhances energy efficiency, and extends roof lifespan.

Fading, chalking, or minor rust spots indicate the need for re-coating.

Cleaning and repairing any damage ensures optimal adhesion and results.

Acrylic, silicone, and polyurea coatings are common options, each suited for different conditions.

Technicians apply coatings using specialized equipment for even coverage.

Visual improvements demonstrate the protective and aesthetic benefits.

Proper surface preparation is crucial before applying the coating.

A durable, reflective surface that helps maintain roof integrity.

Little measurements that prevent headaches on Metal Roof Coating Service day.

A 60-second routine that keeps Metal Roof Coating Service looking new.

A frequent mistake in Metal Roof Coating Service and how to dodge it.

Small tweaks to make Metal Roof Coating Service safer and easier to use.

| Season | Ideal Conditions |

|---|---|

| Spring | Moderate temperatures, low humidity, and minimal rain. |

| Summer | Early mornings or late afternoons to avoid heat extremes. |

| Fall | Stable weather, cool temperatures, and dry conditions. |

| Winter | Not recommended due to potential freezing temperatures and moisture issues. |

Applying metal roof coatings during optimal weather conditions ensures the best results. Proper timing reduces the risk of coating failure, such as peeling or improper curing. Regularly scheduled coatings, particularly during the recommended seasons, can help maintain roof performance and appearance. It is advisable to consult with professionals to determine the best timing based on local climate patterns.

Specialized sprayers ensure even application across the roof surface.

Monitoring conditions helps schedule coating for optimal results.

Cleaning and repairing before coating is essential for durability.

A sleek, reflective surface ready to withstand the elements.

Lower-waste or water-saving choices for Metal Roof Coating Service.

The short, realistic tool list for quality Metal Roof Coating Service.

Rough timing from prep to clean-up for Metal Roof Coating Service.

Quick checks and paperwork to keep after Metal Roof Coating Service.

Timing is a critical factor in the success of metal roof coating projects. Properly scheduled applications not only improve adhesion but also enhance the longevity of the coating. Weather conditions such as high humidity, rain, or extreme temperatures can compromise the process, leading to subpar results. Consulting with experienced professionals can help determine the most suitable time frame for coating to ensure maximum protection.